Small scale vegetable oil refinery machine working process

Our small scale vegetable oil refinery machine have three advantages, which are simple devices, less investment, flexible process. It is applicable to 1-10tpd small scale vegetable oil refinery plant.

Small scale vegetable oil refinery machine

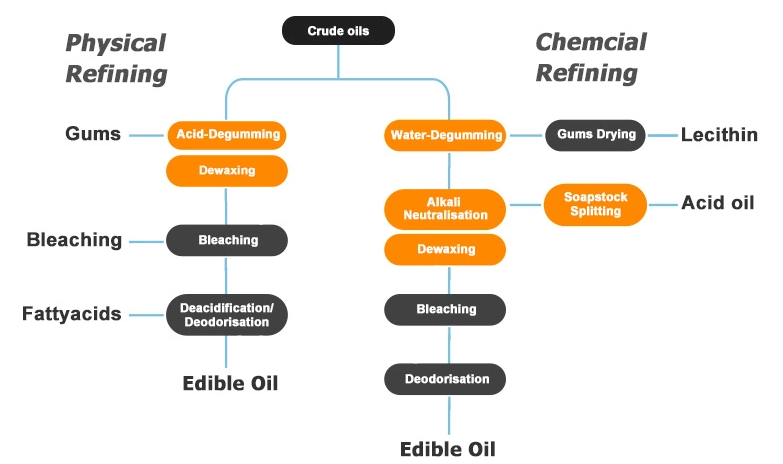

Small scale vegetable oil refinery plant process:

The process of small scale vegetable oil refinery plant

Cooking oil refining process detailed introduction:

Deacidification:

Add some certain quantity of alkali to neutralize the free fatty acids. During this process, some soapstock will be produced.The soapstock will be separated from the oil after using the centrifugal machine.

Degumming:

The purpose of degumming is to remove the phospholipid, sugar, protein, trace mental, and some other impurities, which have bad effect on the stability of the oil. First, the oil should be heated to 90to105°C, then put some phosphoric into it and stir. It mainly transfer the phospholipid to that can be compatible with water. Then add some salt water to gather the impurities, which subside to the bottom and be discharged.

Decolorization:

Mix the oil with activated clay in the oil soil mixing tank, and 1 ton oil needs 5kg clay. Then stir it 10 minutes at 10°C. Next, pump the mixed oil into the decolorization tower. It use steam to heat the mixed oil at 100°C, and the process lasts 30-40 minutes.

Deodorization:

The main purpose of deordorization tower is to remove fatty acid and some odor material. The principle of the deordorization is to use the high temperature and vacuum to remove the odor. The fatty acid and odor will be stalled in the storage tank.

Dewaxing:

Dewaxing can improve oil palatability,so it plays an importan role to the quality of finished oil.At the same time,dewaxing can improve oi transparency and brightness. It is necessary to dewax for some oils such as maize oil,rice bran oil,sunflower oil and cottonseed oil. At present , wintering method is very popular to deawxing.The crystallizing rate crystallizing temperature, maturing time vary with oil features.

Our company, Henan Doing Mechanical Equipment Co.,ltd, is very professional in manufacturing vegetable oil refinery machine. Our vegetable oil refinery machine is of high quality, and has already exported many countries. Our engineer will help you to select the most suitable machines for you. Welcome to enquiry! Ask for latast quotation.

Contact: MsSophia

Skype: sophia.zang1

Whatsapp: 0086 135 2662 7860

Phone: +86 135 2662 7860

Tel: +86 371 5677 1823

Email: oilmachine@doinggroup.com

website: http://www.edibleoilrefinerymachine.com

Know more:

/image%2F2840587%2F20180602%2Fob_bf5945_logo.jpg)

/image%2F2840587%2F20180828%2Fob_36b252_.jpg)

/image%2F2840587%2F20180825%2Fob_f441e7_small-vegetable-oil-refinery-plant.jpg)

/http%3A%2F%2Fi.ytimg.com%2Fvi%2F7Wk9dtMDri0%2Fhqdefault.jpg)

/http%3A%2F%2Fi.ytimg.com%2Fvi%2FTly7IBllE4Y%2Fhqdefault.jpg)